Real-time Oil Well Monitoring System with iRTU

System Introduction

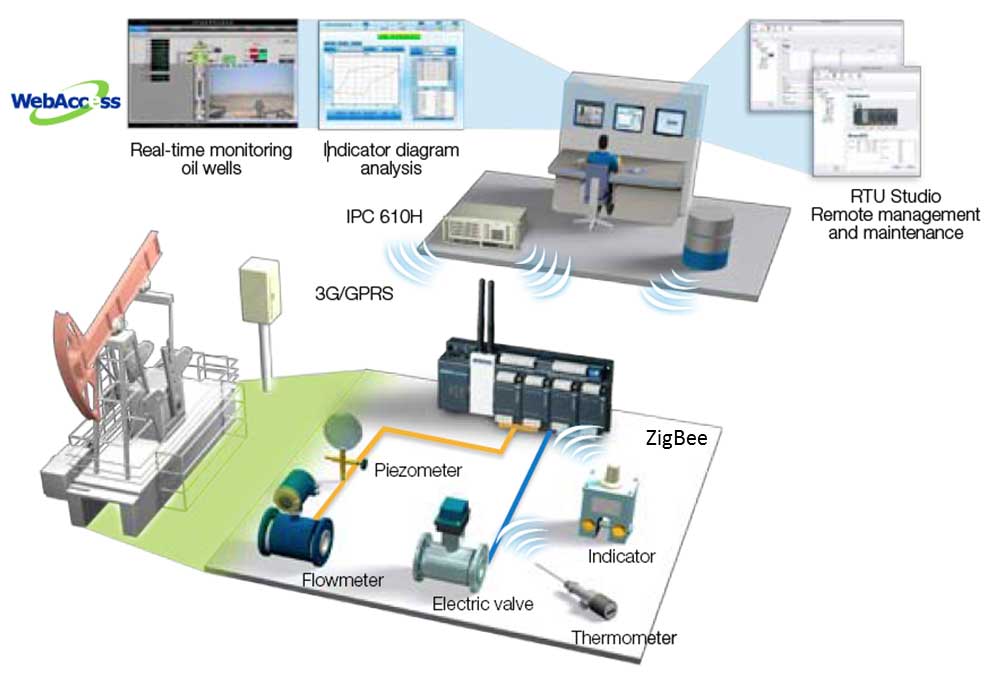

In recent years, the rapid development of information technology has popularized calculator technology, control technology and network communication technology, therefore, establishing the costs of the remote monitoring system is no longer unattainable. Exploiting oil and gas fields needs to use the wide-area remote monitoring system, to monitor the output efficiency of oil and gas and the operation condition of machines and tools.

System Requirements

- Measure and record the oil temperature, sleeve temperature, oil pressure, flow velocity and other parameters of the pump unit, read and store the information of the indicator, and upload it to the center. In addition, Zigbee needs to be connected to the wireless temperature and pressure and other sensors in the field.

- Easy installation and maintenance. When the different wellheads have different monitoring requirements it’s easy to adjust them.

- Oil well production information must be able to correspond to the state parameters of machines and tools, to diagnose the operation efficiency of wellhead, and provide the basis for the deployment of upper system.

- Events must have their own time scale, to provide the basis for subsequent reviews and improvements.

- Remotely monitor the system status and upgrade the software functions.

System Description

When using the open system architecture of the ADAM-3600, two types of wireless communication (3G and Zigbee) can be installed, to collect the wireless sensor data in the field and remotely communicate with the cloud. The ADAM – 3600 with an I/O outgoing line at the top and bottom, is especially designed for control cabinet installation, the front has marks and lights, which can be used to identify the state and detect the faults. Four small expansion slots can be installed between the sites, tomeet different needs. The internal open architecture of the ADAM–3600 is easy to program and maintain and customers can process the data in the RTU whilst also remotely transmitting data for large amounts of data analysis. The ADAM-3600 includes iRTU Studio which customers can use to perform remote configuration, upgrades and updates, to save manpower and material resources.

Project Implementation

- ADAM-3600-C2G: 8AI / 8DI / 4DO / 4-Slot Expansion Wireless Intelligent RTU

- Advantech WebAccess: Browser-based HMI/SCADA Software

- IPC 610H: 4U Rackmount Chassis with Visual Alarm Notification